技术数据 tech data

1 | 机器尺寸 Machinery size | 2000*830*1200 2000*830*1200 |

2 | 机器重量 Machinery weight | 400KG |

3 | 电源 Supply power | 单相 220V±5% 50HZ-60HZ 10A Single phase220V±5% 50HZ-60HZ 10A |

4 | 功率 Power | 1.5KW |

5 | 支持文件格式 Support file format | DXF, AI |

6 | 环境温度 Temperature | 5 度-35 度 5°-35° |

7 | 气源 Air pressure | ≥6 公斤/平方厘米,直径 8 毫米气管 ≥6kg/cm2, ¢8mm air pipe |

8 | 适合刀材高度(注) Rule highness (note) | 23.8 毫米 (标准),其他规格刀材(8-30 毫米)可选配模具。 23.80mm (standard), the other rule can be made as request (8-30mm) |

9 | 适合刀材厚度(注) Rule thickness (note) | 0.71 毫米(标准),其他规格可选(0.45-1.07)可选配模具。 0.71mm (standard), the other rule can be made as request (0.45- 1.07mm) |

10 | 弯刀外模外径 Bending mould outside diameter | 28 毫米(标准),其他规格可选 ¢28mm (standard), the other size can be made as request |

11 | 最大弯曲角度 Max bending angle | 90° |

12 | 最小弯曲圆弧半径 Min bending arc diameter |

0.5mm |

13 | 最大弯曲圆弧半径 Max bending arc diameter |

800mm |

14 |

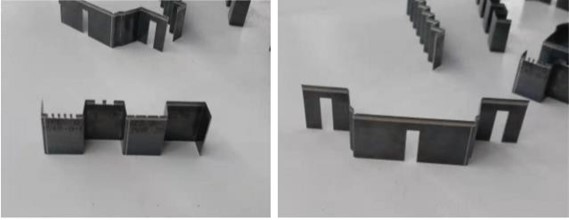

加工特性 Cutting shape | 扭断、桥位、鹰嘴、平切、磨边、齿刀和连点(快速换模装置,可根据刀材规格选配模具) twist off, lip, notching,cut,broaching,perforating and nicking(All moulds can be quickly replaced, the moulds can be selected by rule) |

15 | 桥位规格 Notching size | 宽 5.5 毫米,高度 15.6-18.6 可调(标准),其他规格可订。 width: 5.50mm, high: 15.6-18.6(standard), the other size can be made as request |

16 | 盘刀架 Coil-trolley | 自动升降盘刀架 Common trolley(The automatic Coil-trolley can be selected by your request) |

注:以上是标配,其他尺寸可根据客户的不同需求订制

Note: the above size is standard, the other can be customized accroding to customer’s needs.